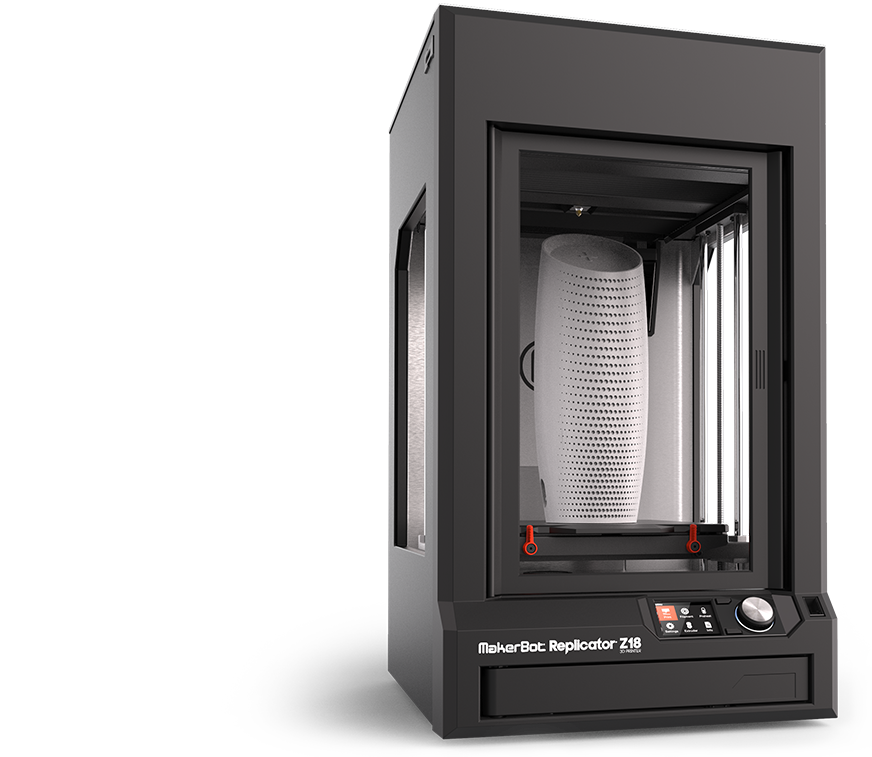

MAKERBOT Z18

The MakerBot Replicator Z18 was designed to provide a massive build volume in a small form factor and lower price point to allow designers and makers to dream bigger. The heated chamber and integrated spool drawer and filament routing helped to ensure prints are more consistent and the machine is easy to use.

My job as a Mechanical Engineer was to design the chamber heating system and housings for the Z18. I worked with the Industrial Design team to discover innovative methods to create large cosmetic panels that achieved the design intent while also making assembly and storage better for the production line. Using a custom machined aluminum composite panel, I was able to create panels that could be shipped to the factory in a flattened state but can be assembled by a single operator into a 3D form.

In addition to the cosmetic panels, I was responsible for the design and testing of the chamber heating system. This system enabled the entire build volume to be heated to the glass transition material of the filament, reducing the curl and defects seen when 3D printing large models.

This 3D printer was initially assembled in our Brooklyn factory, but was later transferred to a Contract Manufacturer in China. As a result, I spent weeks overseas vetting Injection Molding vendors and training our factory on how to efficiently build and test these machines.